Attachments

Showing 1–12 of 97 results

-

Digga 10 & 11 Series augers: 20-50T

Read more Read more

Read moreOur 10 & 11 Series augers suit Backhoes, Excavators, large Telehandlers, and machines up to 50t. For efficient drilling, we designed effective auger cutting heads, so depending on ground conditions, you can choose between a tapered cutting head, or rotating rock picks. For extra length, we also have a full range of auger extensions.

Australian made quality

With over 30 years of auger design and manufacturing using the highest quality material, Digga augers boast extremely efficient cutting head designs, heavy duty tubing, and optimum flight pitches to provide maximum spoil removal in all ground conditions.

RC10/RC11 earth/rock

Digga’s RC10 & RC11 Augers come with tapered tungsten TAPERLOC teeth, which are designed for drilling in earth, shale, asphalt, permafrost and fracturable rock.

DR11 dedicated rock

DR augers feature rotating rock picks for drilling from soft fracturable rock to very hard rock. Featuring short flighting, the design encourages regular spoil removal, allowing cool air to enter the hole, and facilitate regular tooth inspection. Watch our rock auger overview video.

Quick View -

Digga 2 Speed High Flow 15-22T Auger Drives

Read more Read more

Read moreDigga’s 2 speed drilling auger drives for High flow machines have been designed for a wider range of applications. Offering a high speed, low torque setting for the smaller auger jobs when you need that extra RPM, and low speed, high torque for when you really need to grind out that larger diameter hole. It’s like having 2 drive units in 1.

Two speed drives suit excavators & skid steer loaders, truck cranes, front end loaders, wheeled loaders, and backhoes.

- Improved motor design & performance with 2 Speed options:

- Low speed – High torque for large holes

- High speed – Low torque for smaller holes

- Suitable for a wide range of ground conditions:

- Soft loose soils, hard soils, and rocky conditions

- Integrated PRV (Pressure Relief Valve)

- Simple electrical connection:

- 12 or 24 volt coil, just requiring connection

- Optional joystick switches, floor mounted switches & cigarette plugs available pre-wired to suit

- Low maintenance with 5yr gear box and 3yr motor warranty

Quick View - Improved motor design & performance with 2 Speed options:

-

Digga 2 Speed High Flow 20-50T Auger Drives

Read more Read more

Read moreDigga’s 2 speed drilling auger drives for High flow machines have been designed for a wider range of applications. Offering a high speed, low torque setting for the smaller auger jobs when you need that extra RPM, and low speed, high torque for when you really need to grind out that larger diameter hole. It’s like having 2 drive units in 1.

Two speed drives suit excavators & skid steer loaders, truck cranes, front end loaders, wheeled loaders, and backhoes.

- Improved motor design & performance with 2 Speed options:

- Low speed – High torque for large holes

- High speed – Low torque for smaller holes

- Suitable for a wide range of ground conditions:

- Soft loose soils, hard soils, and rocky conditions

- Integrated PRV (Pressure Relief Valve)

- Simple electrical connection:

- 12 or 24 volt coil, just requiring connection

- Optional joystick switches, floor mounted switches & cigarette plugs available pre-wired to suit

- Low maintenance with 5yr gear box and 3yr motor warranty

Quick View - Improved motor design & performance with 2 Speed options:

-

Digga 2 Speed High Flow 30-50T Auger Drives

Read more Read more

Read moreDigga’s 2 speed drilling auger drives for High flow machines have been designed for a wider range of applications. Offering a high speed, low torque setting for the smaller auger jobs when you need that extra RPM, and low speed, high torque for when you really need to grind out that larger diameter hole. It’s like having 2 drive units in 1.

Digga’s SD two speed drive range for drilling suits large excavators & truck cranes with flows up to 380 lpm.

- Improved motor design & performance with 2 Speed options:

- Low speed (low RPM) – High torque for large holes

- High speed (high RPM) – Low torque for smaller holes

- Suitable for a wide range of ground conditions:

- Soft loose soils, hard soils, and rocky conditions

- Integrated PRV (Pressure Relief Valve)

- Simple electrical connection:

- 12 or 24 volt coil, just requiring connection

- Optional joystick switches, floor mounted switches & cigarette plugs available pre-wired to suit

- Low maintenance with 1yr gear box and 1yr motor warranty

Quick View - Improved motor design & performance with 2 Speed options:

-

Digga 2 Speed High Flow up to 15T Auger Drives

Read more Read more

Read moreDigga’s 2 speed drilling auger drives for High flow machines have been designed for a wider range of applications. Offering a high speed, low torque setting for the smaller auger jobs when you need that extra RPM, and low speed, high torque for when you really need to grind out that larger diameter hole. It’s like having 2 drive units in 1.

Two speed drives suit excavators & skid steer loaders, truck cranes, front end loaders, wheeled loaders, and backhoes with flows between 40 and 180 lpm.

- Improved motor design & performance with 2 Speed options:

- Low speed – High torque for large holes

- High speed – Low torque for smaller holes

- Suitable for a wide range of ground conditions:

- Soft loose soils, hard soils, and rocky conditions

- Integrated PRV (Pressure Relief Valve)

- Simple electrical connection:

- 12 or 24 volt coil, just requiring connection

- Optional joystick switches, floor mounted switches & cigarette plugs available pre-wired to suit

- Low maintenance with 5yr gear box and 3yr motor warranty

Quick View - Improved motor design & performance with 2 Speed options:

-

Digga 2 Speed Std Flow up to 8T Auger Drives

Read more Read more

Read moreDigga’s 2 speed drilling auger drives for standard flow machines have been designed for a wider range of applications. Offering a high speed, low torque setting for the smaller auger jobs when you need that extra RPM, and low speed, high torque for when you really need to grind out that larger diameter hole. It’s like having 2 drive units in 1.

Two speed drives suit excavators & skid steer loaders, truck cranes, front end loaders, wheeled loaders, and backhoes with flows between 20 and 150 lpm.

- Improved motor design & performance with 2 Speed options:

- Low speed – High torque for large holes

- High speed – Low torque for smaller holes

- Suitable for a wide range of ground conditions:

- Soft loose soils, hard soils, and rocky conditions

- Integrated PRV (Pressure Relief Valve)

- Simple electrical connection:

- 12 or 24 volt coil, just requiring connection

- Optional joystick switches, floor mounted switches & cigarette plugs available pre-wired to suit

- Low maintenance with 5yr gear box and 3yr motor warranty

Quick View - Improved motor design & performance with 2 Speed options:

-

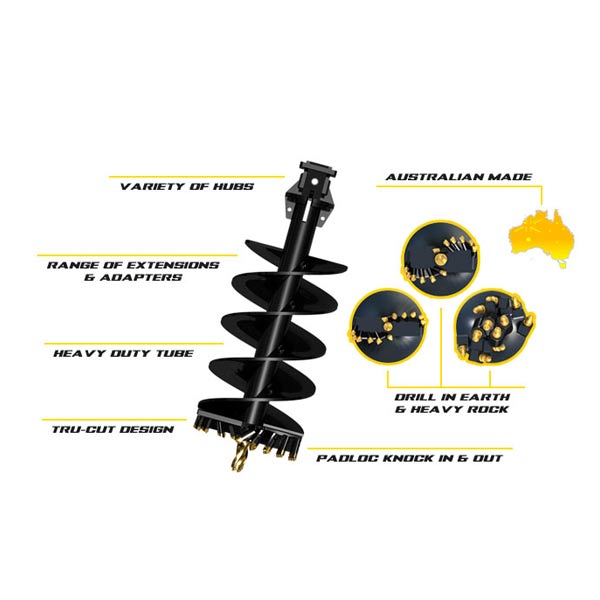

Digga 4 Series augers: 5T

Read more Read more

Read moreOur 4 Series augers boast effective cutting heads for efficient drilling, and suit mini loaders, skid steer loaders, and excavators up to 5T. Depending on ground conditions, you can choose a bladed or tapered cutting head, or rotating rock picks. For deeper holes, a full range of auger extensions are available for your specific requirement.

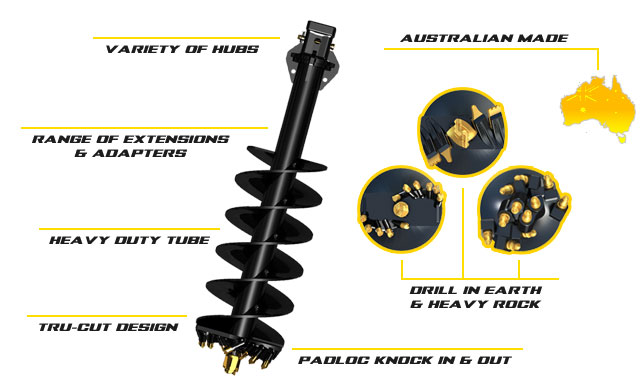

Australian made quality

With over 30 years of auger design and manufacturing using the highest quality material, Digga augers boast extremely efficient cutting head designs, heavy duty tubing, and optimum flight pitches to provide maximum spoil removal in all ground conditions.

A4 earth

Drill holes in light earth conditions and clay. Numerous teeth options are available for most ground conditions. Available in Earth, Tungsten, or MFT forgeneral drilling. Easy PADLOC knock in and out teeth require no special tools. Watch our earth auger overview video.

RC4 earth/rock

Digga’s RC4 Augers come with tapered tungsten TAPERLOC teeth, which are designed for drilling in earth, shale, asphalt, permafrost and fracturable rock.

DR4 dedicated rock

DR augers feature rotating rock picks for drilling from soft fracturable rock to very hard rock. Featuring short flighting, the design encourages regular spoil removal, allowing cool air to enter the hole, and facilitate regular tooth inspection. Watch our rock auger overview video.

Quick View -

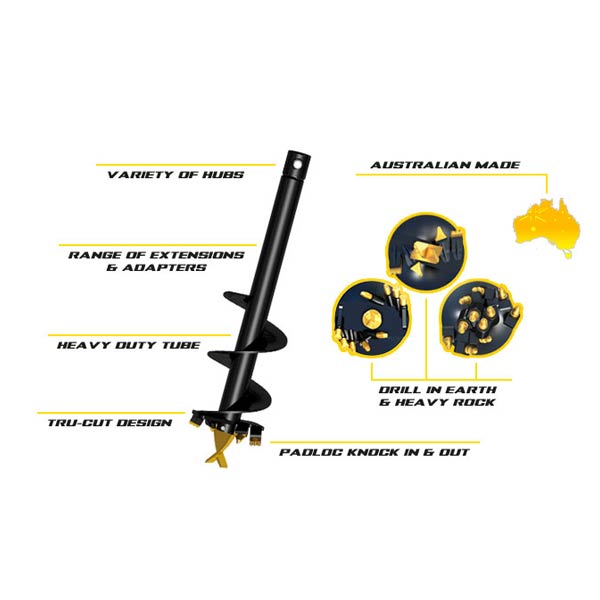

Digga 6 Series augers: 5-10T

Read more Read more

Read moreOur 6 Series augers are suited for large Skid Steers, Tracked Loaders, Backhoes, and Excavators. For efficient drilling, we designed effective auger cutting heads. Depending on ground conditions, choose between a bladed cutting head, a tapered cutting head, or a rotating rock pick. Need something longer? Digga has a full range of auger extensions available to suit your application.

Australian made quality

With over 30 years of auger design and manufacturing using the highest quality material, Digga augers boast extremely efficient cutting head designs, heavy duty tubing, and optimum flight pitches to provide maximum spoil removal in all ground conditions.

A6 earth

Drill holes in light earth conditions and clay. Numerous teeth options are available for most ground conditions. Available in Earth, Tungsten, or MFT for general drilling. Easy PADLOC knock in and out teeth require no special tools. Watch our earth auger overview video.

RC6 earth/rock

Digga’s RC6 Augers come with tapered tungsten TAPERLOC teeth, which are designed for drilling in earth, shale, asphalt, permafrost and fracturable rock.

DR6 dedicated rock

DR augers feature rotating rock picks for drilling from soft fracturable rock to very hard rock. Featuring short flighting, the design encourages regular spoil removal, allowing cool air to enter the hole, and facilitate regular tooth inspection. Watch our rock auger overview video.

Quick View -

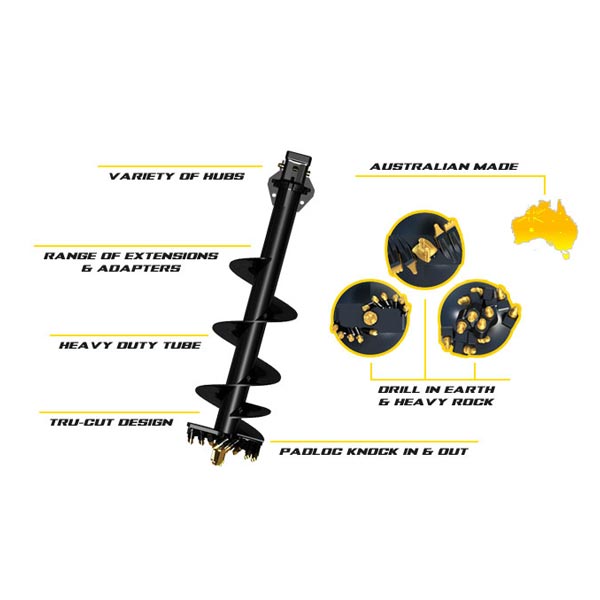

Digga 8 Series augers: 10-30T

Read more Read more

Read moreOur 8 Series augers are suited to Backhoes, Excavators, and machines up to 30t. For efficient drilling, Digga’s effective auger cutting heads let you choose between a bladed or tapered design, as well as a range of rotating rock picks to suit different ground conditions. Need more length? We also have a full range of auger extensions.

Australian made quality

With over 30 years of auger design and manufacturing using the highest quality material, Digga augers boast extremely efficient cutting head designs, heavy duty tubing, and optimum flight pitches to provide maximum spoil removal in all ground conditions.

A8 earth

Drill holes in light earth conditions and clay. Numerous teeth options are available for most ground conditions. Available in Earth, Tungsten, or MFT forgeneral drilling. Easy PADLOC knock in and out teeth require no special tools. Watch our earth auger overview video.

RC8 earth/rock

Digga’s RC8 Augers come with tapered tungsten TAPERLOC teeth, which are designed for drilling in earth, shale, asphalt, permafrost and fracturable rock.

DR8 dedicated rock

DR augers feature rotating rock picks for drilling from soft fracturable rock to very hard rock. Featuring short flighting, the design encourages regular spoil removal, allowing cool air to enter the hole, and facilitate regular tooth inspection. Watch our rock auger overview video.

Quick View -

Digga Agricultural 4 in 1 Bucket

Read more Read more

Read moreAn evolution from the tried and proven design of the Digga 4 in 1 Skid Steer Bucket. Updated to suit the needs of the agricultural industry, while still incorporating many of the features skid steer owners enjoy.

- Standard Heavy Duty 16mm floors

- 20mm floors available on request

- Light weight designed specifically for Agricultural machines

- Full range available from 1500mm to 2200mm

- Grabbing teeth profiled on both the front/rear overlap for greater grip of logs and other debris

- Optional reversible bolt on cutting edges for all

3 edges of the bucket - Chisel or Tiger teeth – pin on design

- Same fitment on tractor as the general purpose bucket

Quick View -

Digga Agricultural series augers to 5T

Read more Read more

Read moreOur Agricultural Series augers are specially purposed for one man Post Hole Borers, 3pt Linkage & front mounted post hole digger tractors, Ramdrills (rear mount tractors), and machines up to 5 tonnes. For efficient drilling, Digga has designed an effective auger cutting head for which, depending on the ground condition, you can choose between a selection of cutting heads – For A1, A3, A4, or TP augers for tree planting. Need something longer? Digga has a full range of auger extensions available to suit your specific requirements.

Australian made quality

With over 30 years of auger design and manufacturing using the highest quality material, Digga augers boast extremely efficient cutting head designs, heavy duty tubing, and optimum flight pitches to provide maximum spoil removal in all ground conditions.

A1 earth

Regulate drilling speed and still maintain the renowned Digga penetrating capabilities. To minimise overrun, and avoid auger jam, the A1 auger has its cutters fitted to one side and features a restrictor plate. A hard working, long lasting, and dependable drilling tool. Easy PADLOC knock in and out teeth require no special tools.

A3 & A4 earth

The A3 is constructed for efficient post hole digging while the A4 is the Contractor’s choice able to drill holes in earth and clay and designed specifically for the tough Australian conditions. Available in Earth, Tungsten, or MFT for general drilling. Easy PADLOC knock in and out teeth require no special tools.

TP – Tree planter

Designed to drill a smaller diameter hole for the tap root and a larger secondary hole at the top for the root ball. The design of the Tree Planter cutting system will leave the hole walls rough and not glazed, meaning the plant stock has the maximum chance of establishing.

Quick View -

Digga Anti Kickback Valve – ECV

Read more Read more

Read moreScrew anchors are installed to an engineering torque specification. By the time installation torque is reached and the operator stops the machine, the pile has built up rotational energy (somewhat like a rubber band on a wind up model aeroplane). This causes the pile to momentarily ‘kick back’,

forcing the energy back up the pile through to the drive shaft, the gearbox, and the hydraulic motor.This action effectively turns the motor into a high speed pump, generating cavitation of the motor, which causes motor failure and expensive replacement costs. Digga’s revolutionary flow reversal bypass valve (ECV) can be fitted to the drive manifold to control the release of this energy.

- Protects motor from rapid oil decompression

- Easily convert your auger drive into a screw anchor drive

- Digga’s Energy Control Valve also known as Swoosh Valve can be fitted to all PD drive units for screw anchoring applications. ECV comes standard on all Digga anchor drives

Quick View

Filter By Categories

- Show value(s)